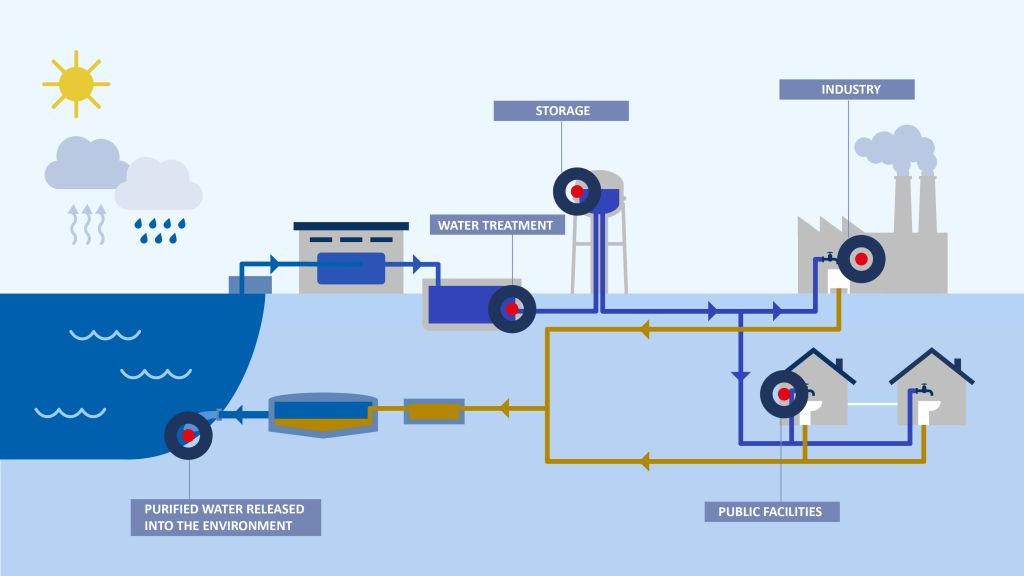

There's little question that water utility companies play a crucial role in providing safe, reliable water services to their communities. Because this mandate has a direct impact on public health, water utility operators and management teams must be able to ensure the water they're providing remains safe throughout the entire process they control which includes analyzing and controlling for bacteria within:

- The water supply, including lakes, rivers, underground aquifers and more

- Water distribution to homes and businesses

- Wastewater treatment

Within each of these stages of municipal water management, Critical Control Points (CCPs) for microbiological analysis should be implemented. In the case of water utilities, let's discuss each of these parts in more detail and how testing and quality control considerations for each can help ensure that water remains safe and reliable as it flows from throughout system to end consumers.

Water Supply

Water utilities source water from a variety of natural sources. Each water source comes with its own set of health and safety considerations. Here are a few common water sources used by water utilities and some potential risk factors:

- Surface water sources (Rivers, Lakes, Reservoirs) are susceptible to contamination from agricultural runoff, industrial discharges, and sewage. Water treatment is usually more intensive for surface water due to the presence of pathogens, sediments, and organic matter. Contaminants like bacteria will need to be effectively removed to ensure safe drinking water.

- Groundwater sources (Wells, Aquifers) are generally less prone to immediate contamination compared to surface water, however, there remains a risk of groundwater contamination from underground sources such as septic systems and industrial activities.

- Reservoirs and storage tanks can be vulnerable to the growth of microorganisms if not properly maintained and cleaned. Biofilm—thin layers of microorganisms— formation and water stagnation can lead to bacterial growth, potentially compromising water quality.

- Spring water comes from underground aquifers and is often considered clean and safe due to natural filtration processes. However, even spring water can become contaminated by nearby human activities or natural events, highlighting the importance of monitoring and testing for bacteria.

Key consideration for water utility operators: Bacterial contamination can be introduced into any water source. Therefore, utility managers must perform fast and accurate regular testing into their protocols to ensure that source water is safe before entering the water distribution system. If contamination is detected, managers must quickly determine the type and quantity of the bacteria to treat effectively.

Water Distribution

A water distribution system comprises various components that work together to deliver safe and clean drinking water. While many components contribute to the overall functionality of the system, some are more susceptible to bacterial contamination than others.

Here are some of the components, and potential bacterial contamination considerations associated with them:

- Pipes can develop biofilms over time. Bacterial growth within these biofilms can lead to reduced water quality and contribute to the regrowth of harmful bacteria, such as Legionella. Stagnant sections of pipes can also provide breeding grounds for bacteria.

- Storage tanks and reservoirs must be properly maintained and cleaned, or they can become breeding grounds for bacteria and other microorganisms. Sediment buildup in tanks can create environments conducive to bacterial growth.

- Cross-connection control devices may introduce bacterial contamination if backflow occurs due to improper installation or malfunctioning between potable and non-potable water sources.

- Backflow prevention devices can become sources of bacterial growth themselves. Regular testing and maintenance are important to ensure their effectiveness in preventing backflow and contamination.

Key consideration for water utility operators: Bacterial contamination can occur during any point of water distribution. Regular testing of the water supply must be done to provide fast and reliable results to ensure that only safe, drinkable water is going through the system. Should issue arise around contamination, teams must know what they’re dealing with to treat effectively and quickly.

Wastewater Treatment

The majority of municipalities have complex infrastructure set up to treat and manage the waste generated from domestic, industrial, and commercial sources. The goal is to remove pollutants, contaminants, and pathogens from the wastewater before it's safely released back into the environment.

While these systems are designed to effectively treat wastewater, there are potential health and safety considerations, particularly regarding bacterial contamination. Here are the key components of a wastewater treatment system and their associated considerations:

- Collection systems, including sewer pipes and pumping stations, can potentially harbor bacterial contamination due to the presence of untreated or partially treated sewage. Breaks or leaks in sewer lines can release bacteria into the surrounding environment.

- Screening and pre-treatment, including filters and grit chambers, are used to remove large debris and solid particles from wastewater. These solids can contain bacteria and pathogens, so proper disposal of removed solids is important to prevent environmental contamination.

- Primary treatment involves the settling of suspended solids in wastewater. While it reduces the bacterial load to some extent, the effluent can still contain harmful bacteria. Effective disinfection is necessary before discharge.

- Secondary treatment (biological treatment) uses microorganisms to break down organic matter in wastewater. While this process reduces bacterial populations, it also introduces a significant amount of bacteria into the system. Proper control of the treatment process is essential to prevent the release of harmful bacteria into the environment.

- Tertiary treatment further refines the effluent to remove remaining contaminants. Disinfection through methods like chlorination or ultraviolet (UV) treatment is crucial to kill harmful bacteria before discharge.

- Disinfection is a critical step to eliminate or reduce bacteria and pathogens in the treated wastewater. Proper dosage and monitoring of disinfection agents are essential to ensure effective bacterial control without creating harmful disinfection byproducts.

- Sludge treatment and disposal deals with byproduct of wastewater treatment and require careful management to prevent bacterial contamination of soil, water bodies, and the atmosphere.

- Odor control is necessary because bacterial processes in wastewater treatment can produce foul odors. Proper odor control measures are necessary not only to prevent nuisance but also to reduce the risk of harmful bacterial aerosols being released into the air, such as those containing Legionella.

Key consideration for water utility operators: Wastewater by its very definition must be considered biologically contaminated. Therefore, regular testing should be performed after each cleaning phase to ensure any water released back into the environment is safe from biological threats.

Bringing It All Together

Water utility companies face risks with from biological contamination at all stages of water management from supply sources, distribution systems, and wastewater treatment efforts. At each stage, or CCP, quick, accurate and repeatable testing by operators is critical to prevent risk to both consumers and the community more generally.

Water testing in this environment is time-sensitive and cannot wait for lengthy lab results or risk an incomplete picture of the bacterial contamination threat. Both of these situations are common with some older testing methods. Instead, water utility operators need a testing system that is fast, reliable, and has the portability to allow them to easily bring that diagnostic accuracy to any part of the water utility system as needed.

This is precisely what rqmicro.COUNT does.

rqmicro.COUNT is a small, portable, and rapid microbiological water analysis instrument that uses flow cytometry, which is an optical single-cell counting technology that can provide accurate, reliable results. rqmicro.COUNT is easily deployed on-site; Water utilities can bring the unit to provide for regular CCP testing for water sources, distribution, wastewater treatment, or any particular situation in the system where there may be suspected bacterial contamination.

By the using flow cytometry, rqmicro.COUNT reduces the time needed for analysis —and eliminates the added logistics that older cultivation methods require, both in terms of transport water samples back to the lab for analysis and then waiting for results. Indeed, rqmicro.COUNT can generate reliable and accurate water sample results in just 30 minutes.